Valsak Service Quality

At valsak our goal is to fully meet the needs and wishes of our customers. We are constantly investing in new products and modern production methods in order to satisfy the most demanding customers quickly and reliably.

At Valsak, we have the ability to identify and produce products that meet specific market requirements. Whether the products are small or large-scale orders, we can tailor our solutions to meet your specific needs. In addition, we offer the ability to differentiate packaging, whether it be unique designs or different material and size options, in order to highlight your product and match your customers' preferences.

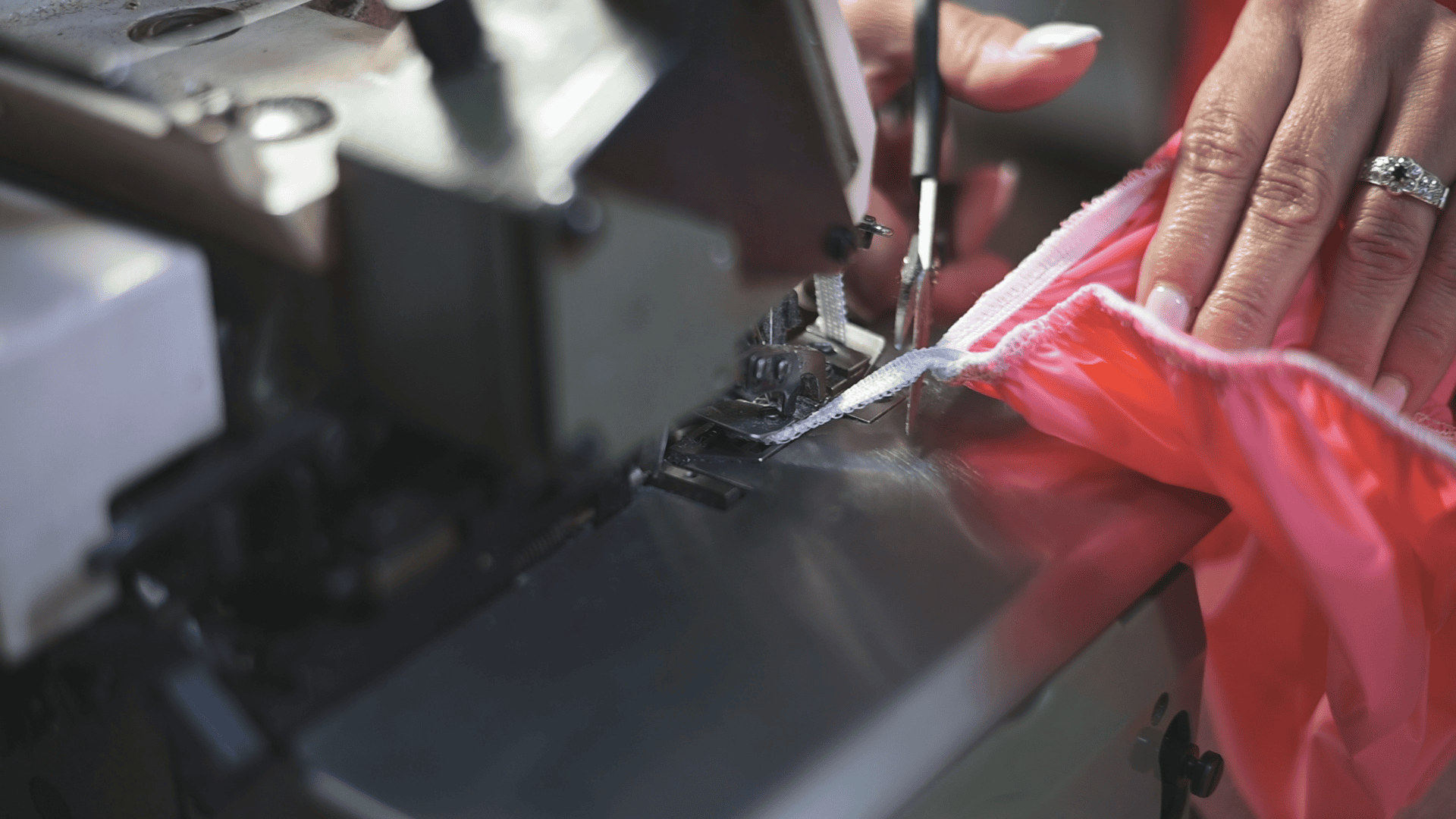

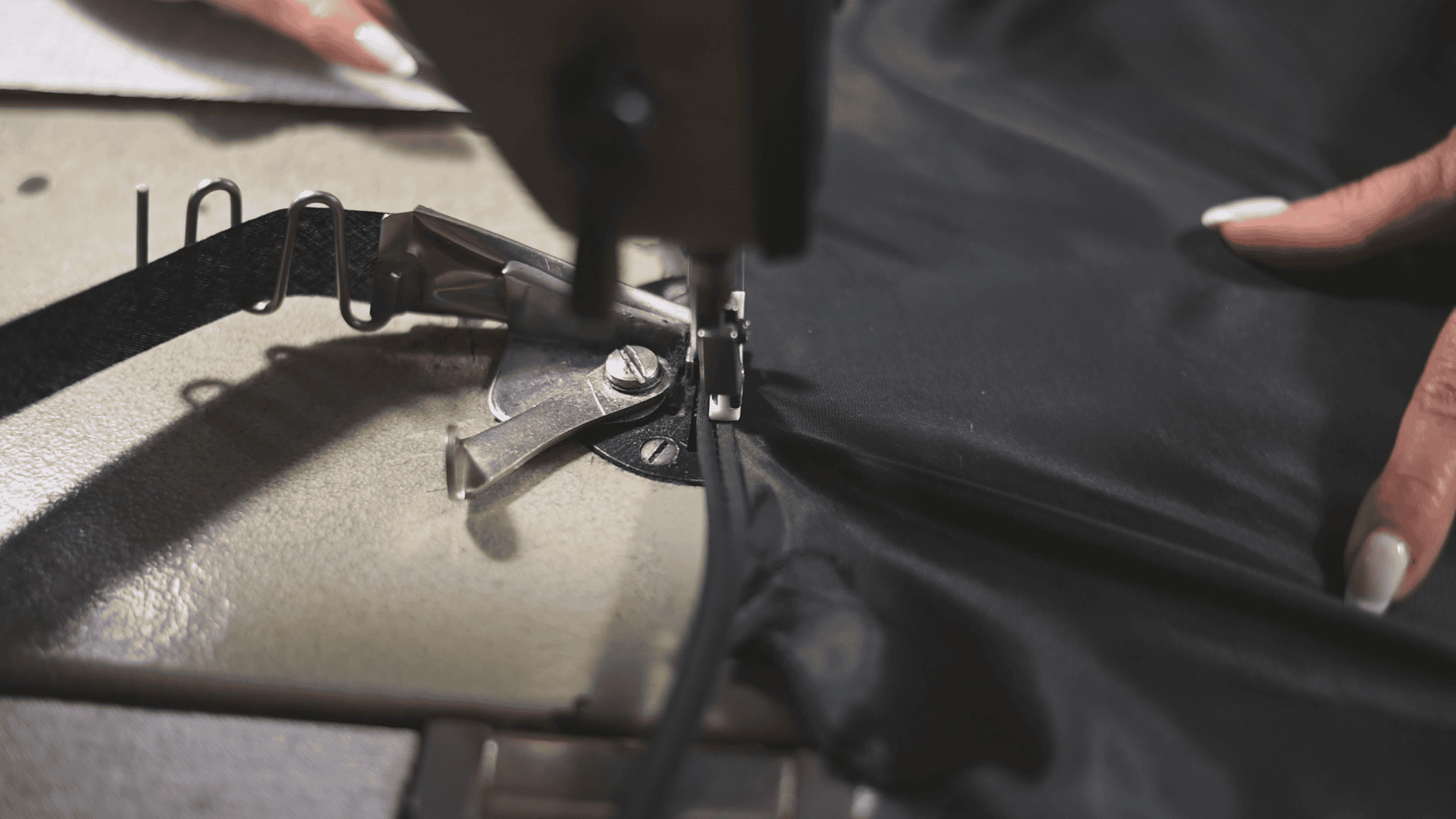

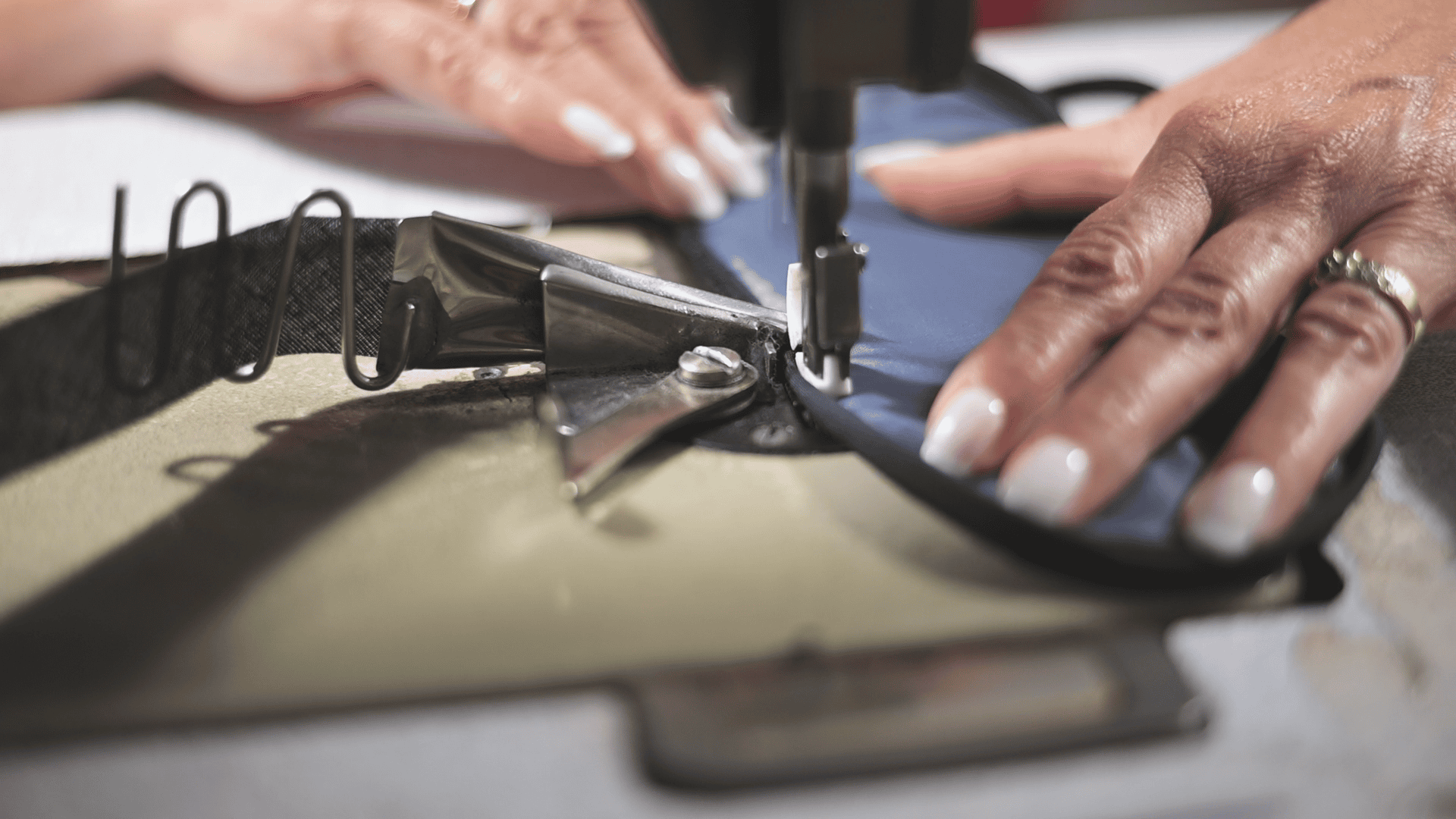

Sewing machines

A sewing machine is a machine used to sew fabrics and other materials, replacing the hand and speeding up the process of producing garments, accessories, and other woven products. By providing production by hand the sewing machine makes our products durable and longer lasting. It does not allow errors as every movement is controlled by the human hand. By using the sewing machine we achieve the highest quality performance of our Greek raw material in all our products (haircuts, sleeping masks, hair ribbons and male friends.

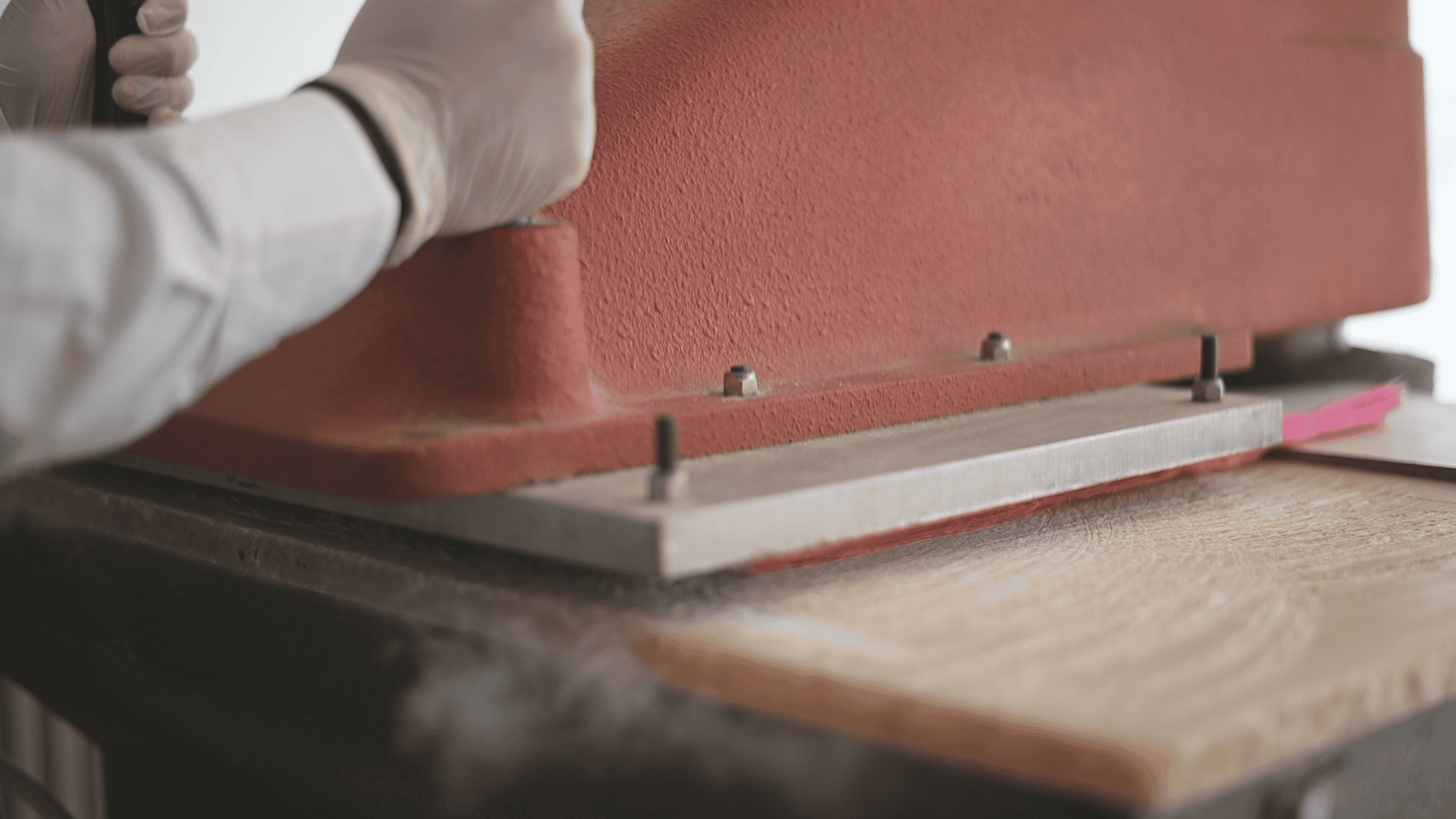

Material folding machines

The material wrapping machines are designed exclusively to facilitate the company's production. With a special construction they simplify the folding of fabrics, plastics and other materials. Designed to fit every human hand and easy to handle, they play a decisive role in the rapid transfer of raw material into smaller quantities for the production of the company's products.

They have high efficiency and accuracy

They have high efficiency and accuracy

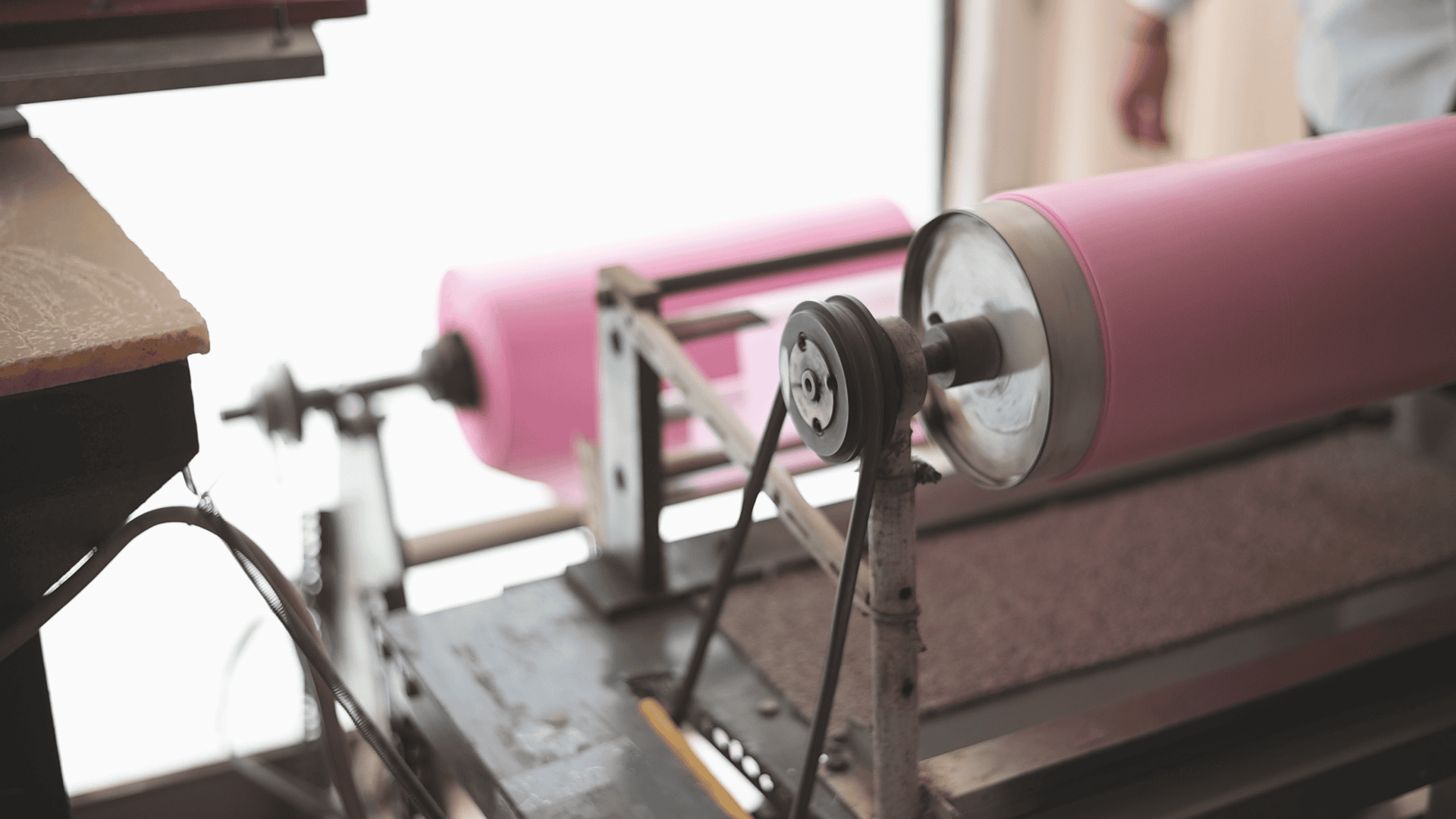

Reliastra

They are tools used in the sewing and textile industry to treat the edges of fabrics to avoid fraying and ensure a clean and professional appearance. These tools are used to 'wrap' or sew the edges of fabrics in various ways, depending on the use and type of fabric.

Operation of the fabric grippers:

1. Avoiding overlocking. This process prevents fraying of the fabric and creates a clean, professional finished look.

2. Technique: Belay stitches work by using several stitches and threads, creating a series of parallel seams around the edge of the fabric. They also incorporate the use of a special triangular or circular tooth that helps to close the edges of the fabric with a professional effect.

Operation of the fabric grippers:

1. Avoiding overlocking. This process prevents fraying of the fabric and creates a clean, professional finished look.

2. Technique: Belay stitches work by using several stitches and threads, creating a series of parallel seams around the edge of the fabric. They also incorporate the use of a special triangular or circular tooth that helps to close the edges of the fabric with a professional effect.

Coptoraptor

An overlocker (or overlock machine) is a specialized sewing machine used for cutting, sewing and finishing the edges of fabrics. It is ideal for preventing fraying and provides a clean, professional look to seams.

Key Features

1. Cutting and Sewing Together

The overlocker cuts and sews at the same time.

The machine's jaws cut the edge of the fabric, while the stitching prevents fraying.

2. Multiple Threads

Unlike traditional sewing machines, it uses 3, 4 or 5 threads.

Multiple threads create stronger and more durable seams.

Allows the production of elastic seams, ideal for stretch fabrics.

3. Speed and Efficiency

Very high speed, ideal for industrial production.

Ability to create a large volume of seams in a short time.

4. Sewing on Round Edges

Ideal for difficult areas, such as armpits and sleeves.

Creates clean seams without distortion.

Key Features

1. Cutting and Sewing Together

The overlocker cuts and sews at the same time.

The machine's jaws cut the edge of the fabric, while the stitching prevents fraying.

2. Multiple Threads

Unlike traditional sewing machines, it uses 3, 4 or 5 threads.

Multiple threads create stronger and more durable seams.

Allows the production of elastic seams, ideal for stretch fabrics.

3. Speed and Efficiency

Very high speed, ideal for industrial production.

Ability to create a large volume of seams in a short time.

4. Sewing on Round Edges

Ideal for difficult areas, such as armpits and sleeves.

Creates clean seams without distortion.